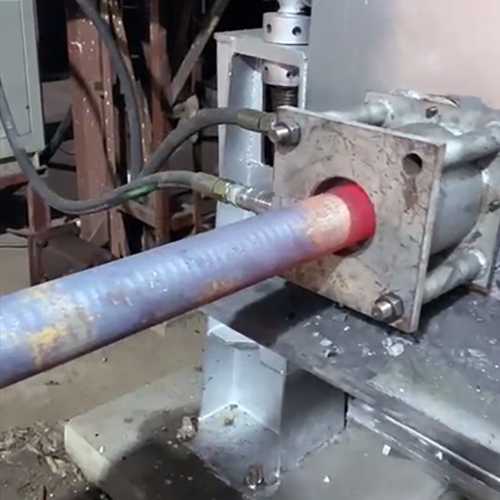

Horizontal Continuous Casting Plant For Rod Casting

Product Details:

- Type Billet Casting Plant

- Material Copper and copper base alloy

- Computerized Yes

- Automatic Grade Automatic

- Click to View more

X

Horizontal Continuous Casting Plant For Rod Casting Price And Quantity

- 1 Unit

Horizontal Continuous Casting Plant For Rod Casting Product Specifications

- Automatic

- Billet Casting Plant

- Copper and copper base alloy

- Yes

Horizontal Continuous Casting Plant For Rod Casting Trade Information

- Cash in Advance (CID)

- 1-2 Months

- All India

Product Description

The Horizontal Continuous Casting Plant for Billet Casting is a high-performance industrial machine designed to cast steel alloy billets in dimensions ranging from 20 to 200 millimeters. With its automatic feature and frequency speed control system, it guarantees efficient and accurate casting of billets. This casting plant is suitable for various industrial applications that require high-quality billets, including the manufacturing of pipes, rods, and wires. The machines durability and reliability ensure long-term use without compromising the quality of the billets produced.

Other Details:

FAQs of Horizontal Continuous Casting Plant For Billet Casting:

Q: What is the maximum dimension of billets that can be cast using this machine?

A: The Horizontal Continuous Casting Plant for Billet Casting can cast billets with dimensions ranging from 20 to 200 millimeters.Q: Does this machine come with computerized controls?

A: Yes, this machine has computerized controls.Q: What type of control system does this machine have?

A: This machine comes with a frequency speed control system that ensures accurate and efficient casting of billets.Q: Does this machine have a touch screen feature?

A: Yes, this machine have a HMI screen.Q: What is the general use of this machine?

A: The Horizontal Continuous Casting Plant for Billet Casting is designed for industrial use, particularly in the manufacturing of pipes, rods, and wires that require high-quality billets.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS